Construction workers face numerous kinds of hazards in their day-to-day site activities. In the Nepalese context occupational hazards are even more pronounced in several construction sites where, more often than not, workers’ safety sits at the bottom of the priority. These construction hazards can be different in terms of their likelihood of occurrence as well as the severity of consequences the hazards may bring about. Whether in Nepal or anywhere else in the world, fall, struck-by, electrocution and caught-in (or-between) are the four leading hazards, generally encountered in the construction industry.

Since this group of four-hazards is potentially responsible as well as collectively accounts for a huge number of accidents, injuries and fatalities at construction worksites, the group is often referred as the “Fearsome-4”, “Fatal-Four” or “Focus-Four” hazards. Therefore, every construction site in charge as well as the management leadership must give dedicated attention to alleviate the risks caused by these four hazards. Let’s understand them in a little more detail.

Fall Hazards: present in most of the construction sites

Many workers are exposed to fall hazards on a daily basis. A fall hazard is anything at your worksite that could cause you to lose your balance and result in a fall. Although any walking or working surface can be a potential fall hazard, most common fall hazards in construction are related to unprotected edges, openings, scaffolds and ladders.

Almost all worksites have unprotected sides and edges, wall openings, or floor holes at some point during construction. If these sides and openings are not protected, injuries from falls or falling objects may result in severe injuries. Besides, in the absence of fall protection or safe access to the work front, it is even riskier to work on a scaffold with heavy equipment, building materials and within very limited space. Therefore, the majority of the workers injured in scaffold accidents attributed the accident to factors such as the planking and support giving way, or to the lack of guardrails and other fall protection.

However ordinary it may sound, falls from ladders can also cause deadly injuries. It has been noticed that the factors contributing to falls from ladders are mainly improper ladder selection for a given task, ladder slips (top or bottom supports), overreaching workers, slipping on rungs/steps, not having a portable ladder extended 3 feet above the landing surface and not to mention the lack of adequate training for workers at worksites.

Guardrails, safety net systems and personal fall arrest systems are three generally accepted methods of protection for workers who are exposed to fall hazards in construction sites. In general, it is better to use fall prevention systems, such as guardrails, than fall protection systems, such as safety nets or fall arrest devices, because prevention is more proactive and efficient than having to protect.

There are many ways you can prevent a fall from a ladder in construction sites; starting with choosing the right kind of ladder for the job and tying the top and bottom of the ladder to prevent it from moving sideways or falling backward. Workers should strictly avoid carrying tools or other materials in-hand while climbing the ladder. Rather than carrying tools or other materials in your hands, use a tool belt, install a rope and pulley arrangements, or tie a rope around your materials and pull them up once you have reached the elevated work surface.

Struck-by Hazards: impact between the injured person and an object

In a construction site struck-by hazards can manifest in a variety of ways such as rolling objects and falling objects. Rolling object hazard exists when the worker is struck-by a sliding object (or equipment) or run over by a moving vehicle, whereas falling object hazard exists when the source of injury falls from a height to a lower level.

Flying objects and swinging loads are also commonly observed struck-by hazards in many construction sites. Flying object hazards may include instances when a piece of material, separated from a tool, machine or other equipment, strikes a worker resulting in injuries or fatality. Moreover, stored energy such as compressed air (commonly used to power tools and clean surfaces) can also cause serious flying object hazards.

When materials are mechanically lifted, they have the potential to swing and strike workers as well as visitors standing nearby. This movement can catch workers and bystanders by surprise and they could be hit by the swinging load. In addition to swinging, the lifted loads can also slip from their riggings and accidentally strike the workers.

One of the key protection measures to avoid struck-by hazards in construction sites is to stay away from heavy equipment when it is operating. In fact, be alert around all heavy equipment whether in use or not. Workers should stay clear of lifted or unbalanced loads and never work under a suspended load. Workers should be properly communicated and made aware of the swing radius of cranes and backhoe loaders. Make sure that all workers and visitors are in the clear before operating dumping or lifting devices.

Vehicle safety practices must be carefully observed at construction sites to limit worker exposure to struck-by swinging backhoes, overturning vehicles, and trucks, etc. To avoid these types of hazards at construction zones, workers must wear high-visibility reflective clothing and must avoid getting caught in a situation where there's no escape route. On the other hand, operators and drivers should wear seat belts and routinely check vehicles before each shift to ensure all parts and accessories are in safe operating condition.

Every construction site worker, as well as the visitor, must wear a safety helmet to protect from falling objects as well as bumps to the head from fixed objects. When working with compressed air for cleaning, as part of general safe work practices, workers should use appropriate guarding, proper protective equipment and reduce air pressure to 30 psi. Adequate attention must be given to following proper work procedures while working with hand tools, machinery and power tools. Eye and face protection must be used based on anticipated hazards such as welding, cutting, grinding, exposure to harmful chemicals and flying particles.

Electrocution Hazards: What Could Go Wrong?

An electrical hazard is a serious workplace hazard that exposes workers to Burns (B), Electrocution (E), Shock (S), Arc flash (A), Fire (F), Explosion (E), etc. Therefore, BE-SAFE is the motto for recognizing, avoiding and protecting against all of these electrical hazards in construction sites.All electrical hazards may not prove to be fatal however, electrocution results when a person is exposed to a lethal amount of electrical energy.

With the wide use of power tools on construction sites, flexible extension cords are necessary. Since they are often flexible, unsecured and exposed, they are also more susceptible to damage than the fixed wirings. Hazards are created when cords, cord connectors, receptacles, and other connected equipment are improperly used and maintained.

It is not uncommon to find incidents in construction sites where workers came in contact with energized sources resulting in electrical shock and burns. The severity of an electrical shock depends on a number of factors such as the amount of current, the length of time of the exposure, the pathway through the body, and whether the skin is wet or dry. Electrical burns are among the most serious burns which require immediate medical attention.

Overhead and buried power lines are especially hazardous because they carry extremely high voltage ranging from 120 to 750,000 volts. Workers in the water, sewer, pipeline, road, communication, power line construction and power distribution industries are highly prone to the overhead power line (OHPL) injuries or fatalities. Too often a desire for work convenience, demand for a rush job, and a failure to identify immediate OHPL hazard may combine to cause tragic accidents.

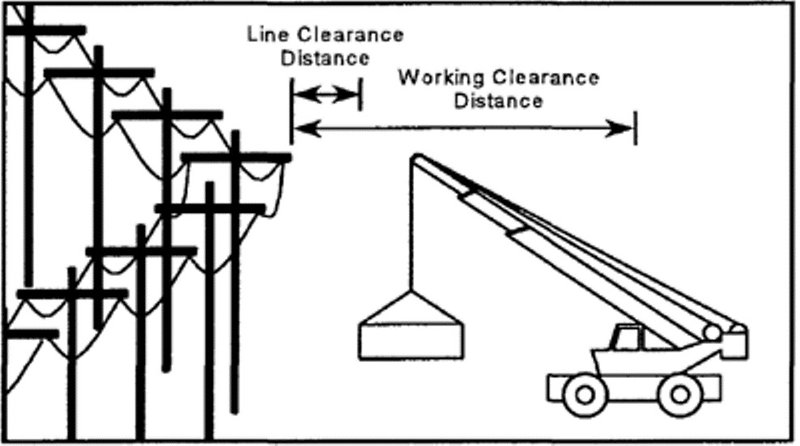

Electricity can be quite unforgiving when proper procedures are not followed, therefore, it is essential that workers are informed, trained and reminded of safe practices/procedures around power lines. Maintaining a safe distance from the overhead power lines is the best option. Make sure that the equipment and activity (such as cranes and other high reaching equipment) are located within a safe working distance from power lines. For up to 200kV power lines, the minimum Line Clearance Distance is 15 feet which increase further as the voltage increases. Moreover, the Working Clearance Distance must be further away from the Line Clearance Distance.

It is important to remember that contact with the OHPL is not necessary to cause injury or death, as arcing can still occur when minimum clearances are not observed. During arcing, workers or equipment can become energized without touching the OHPL directly. If they are working inside the minimum Line Clearance Distance, electricity can arc, or jump across the gap. Besides, the construction workers must be trained to understand the severe consequences associated with the OHPL hazards, to avoid harm from OHPL and to respond in the event of an incident related to OHPL.

Ground Fault Circuit Interrupter (GFCI) is designed to protect people from severe and sometimes fatal electrical shocks. GFCI detects ground faults and interrupts the flow of electric current by limiting the duration of an electrical shock. Unlike multiple GFCI outlets, one GFCI Circuit Breaker can control and protect an entire circuit. It can also be installed as a replacement for a regular circuit breaker on the main circuit board.

To avoid electric shocks workers need to routinely inspect extension cords and other portable tools for any cuts or abrasion. When the insulation of the extension cord is damaged, exposed metal parts in the surrounding may become energized if a live wire inside touches them. Electric hand tools that are old, damaged, or misused may also have damaged insulation inside. Workers need to know that even when the power system is properly grounded, electrical equipment can instantly change from safe to hazardous because of extreme environmental conditions and rough treatment.

Following the Lockout/Tagout procedure is an essential safety measure to protect workers from being electrocuted while working on or near electrical circuits and equipment. Moreover, the lockout/Tagout can also prevent the accidental release of hazardous energy such as gases, fluids, or solid matter during equipment maintenance or repair jobs.

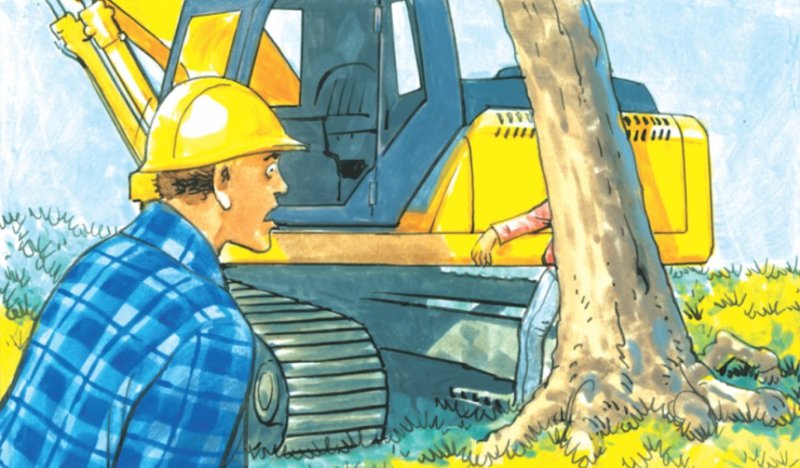

Caught-in (or-between) Hazards: pinned between moving equipment and a solid object

Caught- in (or –between) hazards in construction cause accidents such as cave-ins during excavation, strangulation as a result of clothing caught in running machinery, or being crushed between rolling, sliding, or shifting objects. Please note that the caught–in (or –between) hazards may sound similar to struck-by hazards mentioned earlier. Nevertheless, when the impact alone creates the injury, the event is considered as STRUCK. On the other hand, when the injury is created more as a result of crushing injuries between objects, the event is considered as CAUGHT.

In construction sites when machines or power tools are not properly guarded, workers can get their clothing or parts of their body caught in the machines. If machines are not de-energized (locked out) properly during maintenance, they may accidentally start-up and catch a worker’s body part or clothing causing serious injury or even death.

You should also look out for Caught-in (or-between) hazards during trenching, scaffolding and building demolition.If one is not watchful enough, unprotected trenches and excavations may create the hazard of cave-ins. Workers who are working underneath large scaffolds may also be buried if the scaffolds collapse. Besides, workers could be buried and crushed by walls that may collapse during demolition works.

To protect yourself from caught–in (or –between) hazards, moving machinery parts need to be safeguarded properly. Equipment parts such as belts, gears, shafts, pulleys, spindles, drums, flywheels, chains, or other reciprocating, rotating, or moving parts must be properly guarded, supported and secured at construction sites. Furthermore, make sure to avoid wearing loose clothing or jewelry that may get caught in such moving parts.

At all times be aware of the equipment or vehicles around you and never place yourself between moving objects and an immovable structure such as wall, vehicle, stacked material, etc. As a general safety practice, make sure equipment is de-energized and disconnected when not in use, vehicles are tuned off before repair, power sources (such as electric, pneumatic, liquid fuel, hydraulic, etc.) to the equipment are locked out properly before maintenance work begins, etc.

To protect workers on excavation sites, avoid working in an unprotected trench that is deeper than 5 feet. Implement protective systems such as sloping, benching, trench box, shield, shoring, etc. to prevent trench collapse and cave-ins. Enter or exit a trench or excavation only by using a sturdy ladder, stairway, or properly designed ramp that is placed within the protected area of the trench.

Amit K. Shrestha

Shrestha is a freelance Consultant, MS in Risk Control & Safety Management; The author is passionate about the issues involving environment, occupational health, safety and sustainability for the planet, people and profit. Contact Email: OHSNepal@gmail.co

- Preventing Rapid Climate Change: A Hugely Complicated Taskfor Humanity To Tackle

- Oct 29, 2021

- Changing Perception Changes Everything: A Paradigm Shift In Consciousness

- Aug 02, 2021

- Business Continuity Planning And Disaster Recovery: NRB Guidelines For Commercial Banks of Nepal

- Jun 23, 2021

- Fighting Covid-19: Emotional And Mental Wellbeing Of Essential And Frontline Workers

- May 23, 2021

- COVID-19 Outbreak: Face Coverings Vs Surgical Masks Vs N95 Respirators

- Jul 13, 2020