A construction project, or any other for that matter, is termed a success when a given job is completed in time, within budget and with adequate quality. Every organization essentially strives for reduced cost, minimum lead time, enhanced quality and sustainable growth. In this regard the booming infrastructure and construction sector of Nepal is no exception. However, managers at various construction projects as well as in industrial plants or factories often worry about increased number of accidents, illnesses and environmental/safety compliance issues which eventually affect productivity, thereby obstructing her/his brand to remain competitive in the market. The solution lies in effective implementation and management of Health, Safety & Environment (HSE).

HSE, if not managed properly, can adversely affect any project or organization resulting in loss, delay and reduced quality of the work. To put it simply, HSE works towards creating a work environment and procedures which protect us from injury, illness, damage, danger, loss and environmental impact. Call it safety if you will. But no one can possibly guarantee hundred percent safety at your worksite. According to Murphy’s Law “Anything that can go wrong, will go wrong”. The law implies that there is always some possibility of something going wrong, especially when workers, equipment and complex procedures come together. Appropriate HSE control programs should, therefore, be implemented to reduce this ‘Possibility of Wrong’ to ensure overall safety and sustainability of not only the employees and the project but also the organization and the environment as a whole.

Accidents and Hazards

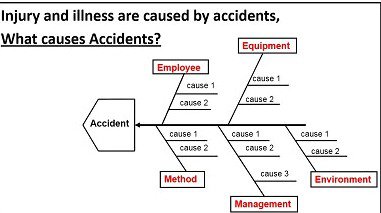

Accidents are one of the biggest concerns in any worksite, be it a construction site or general industry sector. More often than not they bring about injury and illness to the workers as well as loss and delay to the project. This clearly justifies why the goal of any organizational HSE policy is to reduce the number of workplace accidents, injuries and illnesses. If we dig deep enough we find that every accident is rooted in issues related to untrained EMPLOYEE, faulty EQUIPMENT, inappropriate METHOD, poor MANAGEMENT or hazardous work ENVIRONMENT. An effective workplace accident prevention program has two fundamental aspects, namely identifying hazards and controlling the risks posed by those hazards. We will discuss both in this article.

A hazard can simply be defined as anything which has potential to cause harm to workers or the work itself. Earthquake, landslide, flammable substance, smoke & fume, low visibility, working underground, working at height, entering confined space, etc. have the potential to cause harm one way or another thus should be considered as hazards. The immediate cause of every accident is either some kind of Behavioral Hazard or Conditional Hazard present at the worksite. Behavioral Hazards are unsafe human actions, such as inadequate body posture, unsafe equipment use, negligent housekeeping, etc. whereas Conditional Hazards are found in work environment, such as chemical, fire, electricity, pressure, noise, faulty equipment, vibration, fume or even external weather events and disasters.

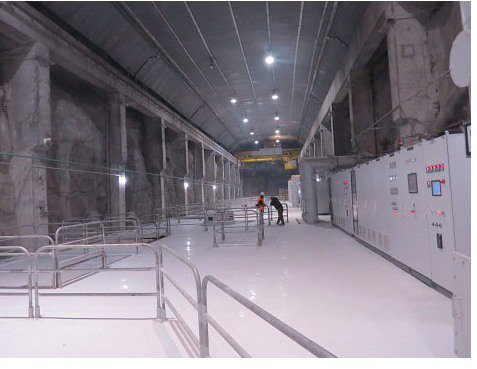

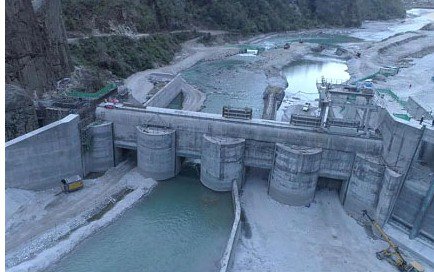

A construction worksite is ridden with all kinds of hazards, such as slip, trip, falling objects, electrocution, falling from height, confined space, chemical spill, caught in machine, stored energy, etc. Moreover, Electrical, Fall, Struck-By and Caught-In or –Between hazards are known as the fearsome four of construction safety. Nevertheless, it is imperative to understand that every hazard has a potential to translate into a risk and then followed by a full-blown accident. When we fail to timely eliminate the source of hazards or mitigate the risks posed by them, we are left to deal with severe consequences of the accident.

From the accident occurrence stand point, hazards can be differentiated into three categories, namely (i) The hazard that has not yet caused any accident or loss, (ii) The hazard that nearly caused accident but without injury or loss and (iii) The hazard that caused accident resulting in injury, illness, fatality or loss. The objective of reducing the number of accidents, in other words reducing the risks of their occurrence, is possible only when we are able to identify the hazards which cause the accidents in the first place. Below we discuss some more details on hazard identification process.

Proactive and Reactive Safety

A proactive safety is the key to success of any HSE program in any organization or construction site. A proactive safety approach is the one where we are able to identify the hazards and control their risks before they turn into accidents and impact workers’ health and safety as well as overall project and the environment. Various factors should be considered while designing and implementing a robust hazard recognition program. Some of them are listed below.

- Take time and pay attention to details to recognize hazards at work

- Recognize the type of hazards; Conditional or Behavioral

- Focus on conditions which may result in serious injury or accident

- Seek opinions from subject matter experts from other departments

- Learn from previous accidents or loss incidents

- Talk to workers and line supervisors about their past experiences

In addition to the above mentioned criteria, utilizing safety related documents, such as work permit, site instruction, method statement, job hazard analysis, risk assessment, standard operating procedure, inspection checklists, etc. can greatly help to identify a wide range of workplace hazards or exposures.

Reactive approach, on the other hand, includes safety measures which are taken after an incident/accident has already occurred. Conventional it may sound, but if pursued sincerely a reactive safety approach could be a life saver. It could help us effectively identify the hazards from the past and mitigate the possibility of similar future accidents from happening. For example, making sure that your work area is free of any slip, trip or fall hazard is proactive safety, whereas fixing such hazards after someone slipped, fell and injured herself or himself is reactive safety.

As suggested by the Murphy’s Law, absolute safety is practically unattainable, however, we can always work towards reducing hazard exposures and mitigating risks in our workplaces. Reduced risk is in fact safety. So it makes more sense to make use of both proactive and reactive approaches to implement appropriate HSE plans and procedures which in turn would help us achieve increased safety by guarding us against the risk of accidents, injuries and illnesses. So, the question is how we mitigate or control the risks prevalent in our construction sites, plants or factories.

Risk Control

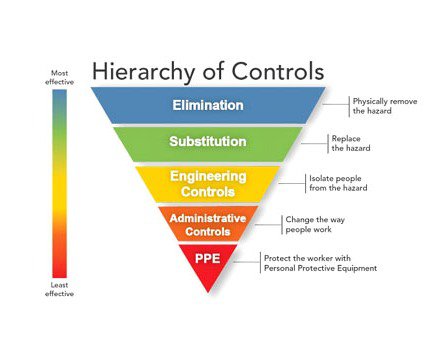

Controlling the risk of exposure to occupational hazards is the fundamental way of preventing accidents, injuries and illnesses at your worksite. Hierarchy of Controls suggests that there are mainly five ways to control the risks at workplaces, namely (i) Elimination, (ii) Substitution, (iii) Engineering Controls, (iv) Administrative Controls and (v) Personal Protective Equipment (PPE). The Hierarchy of Controls ranks those five control options from highest level of protection and reliability to lowest. The idea is to help us determine economically feasible and effective risk control solutions suitable for our worksites.

Elimination and Substitution controls can be achieved through removing the hazards or selecting alternate products or equipment. Sometimes doing the same work in a less hazardous way is possible. For example, a hazardous chemical can be replaced by a less hazardous one. Despite being the most effective control measures, Elimination and Substitution often tend to be difficult to implement in an existing process; major changes in equipment and procedures may be required to eliminate or substitute for an existing hazard.

If a hazard cannot be eliminated or replaced, it can sometimes be isolated, contained or kept away from workers. Thus Engineering Controls help modify existing machinery or suggest purchasing new machinery to provide applicable solution. The idea is to remove the hazard at the source, before it even comes in contact with the workers. Guarding moving parts of a machine or equipment and providing good ventilation system at worksite are some of the examples of Engineering Controls. The initial cost of implementation can be higher but over the time operating costs are frequently lower, and often can provide cost savings in other areas of the process, such as productivity and quality.

Administrative Controls develop new work rules or procedures to reduce the risk of hazard exposure. Both Administrative and PPE Controls are frequently used with existing processes where hazards have not yet been controlled completely by other means. They may be relatively inexpensive to establish but, over the long run, can be very costly to sustain.

Hazard Elimination and Substitution, of all, are the most effective way of controlling workplace hazards. For instance, getting rid of a hazardous job, tool, process, machine or substance is perhaps the best way of protecting workers. However, Elimination and Substitution controls fail to provide practical and economical solutions most of the times. Therefore, we need to look for other options in Engineering, Administrative and PPE Control measures.

Let us consider an example of welding & fire safety at a construction site. Completely eliminating the possibility of welding, cutting or grinding to mitigate the risk of catching fire and exposure to welding fume does not sound practical at all. But we can apply Engineering Controls (such as barricading such hazardous working area, utilizing welding fume extractor, installing proper ventilation system, etc.) and Administrative Controls (such as removing flammable substances from the area, keeping applicable fire extinguishers nearby, etc.) to mitigate the risk. Besides, training your workers on the use of fire extinguisher, enforcing standard welding procedure, organizing job rotation, and assigning fire watch personnel are also some of the effective Administrative Controls to mitigate the risk of fire and exposure to toxic welding fumes.

PPE should be considered the last resort and the least effective way of mitigating the risk of accident, illness and injury at work-sites. It offers the lowest level of protection and should only be used when the hazard exposure cannot be removed or reduced by any other means. PPE Controls (such as steel toe boots, welding apron, leather gloves, safety goggles, respiratory masks, etc.) do not directly control the exposure of the welding, cutting or grinding hazards, however, can protect workers from their negative impact and consequences to certain extent.

Amit K. Shrestha

Shrestha is a freelance Consultant, MS in Risk Control & Safety Management; The author is passionate about the issues involving environment, occupational health, safety and sustainability for the planet, people and profit. Contact Email: OHSNepal@gmail.co

- Preventing Rapid Climate Change: A Hugely Complicated Taskfor Humanity To Tackle

- Oct 29, 2021

- Changing Perception Changes Everything: A Paradigm Shift In Consciousness

- Aug 02, 2021

- Business Continuity Planning And Disaster Recovery: NRB Guidelines For Commercial Banks of Nepal

- Jun 23, 2021

- Fighting Covid-19: Emotional And Mental Wellbeing Of Essential And Frontline Workers

- May 23, 2021

- Fearsome-4 of Construction Industries: Focus on Fatal-Four Hazards

- Jan 27, 2021